Tandem Halfpipe

Halfpipe HP 20 Carrier

Carrier: The well-proven vehicles of the Carrier range are designed to meet the highest demands. Based on an ingenious modular system, they have a firmly specified high-quality standard equipment and are usually available ex stock. Robust earth moving tipper with halfpipe and front press: Krampe Halfpipe HP 20, the classic on europe's constructionsites. Technical changes may be carried out in a limited scope.

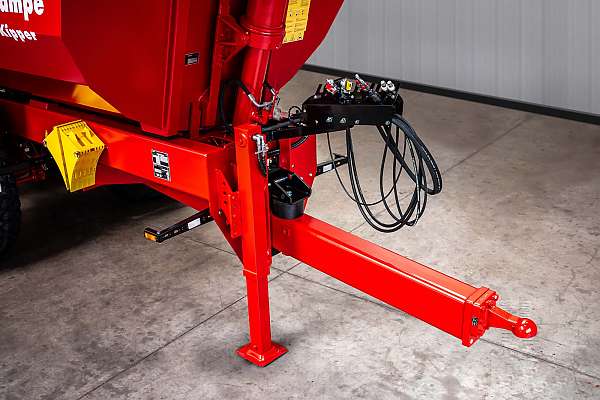

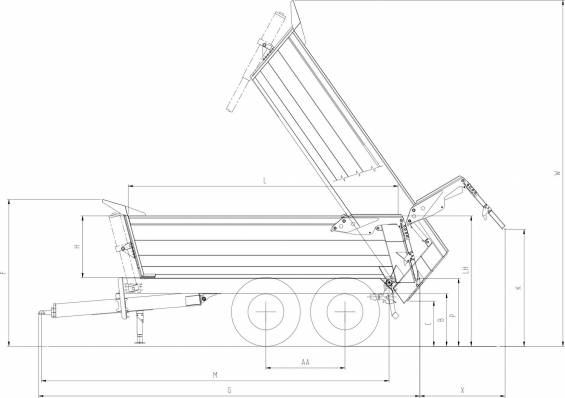

Chassis: Extremely resilient chassis made of large-volume rectangular tube 300 x 150 mm/ suspended, height-adjustable drawbar for low hitch position with flanged 80 mm ball head coupling/ hydraulic support foot with double-acting ram, 6/2 way-valve to combine support foot hydraulic <> rear tailgate/ continuous tipping shaft at rear, heavy rocking ball bearings with a diameter of 80 mm/ hole pattern G 140 for rear trailer coupling/ pendle axle unit with asymmetrically offset axles, easy to pull, optimum ground adjustment due to the very large axle oscillations, good stability on rough terrain during driving but also during tipping/ user-friendly central lubrication bar/ ALB valve/ BPW axles with automatic slack adjusters (ASA)

Body: Stylish halfpipe body, sheet thickness 6 mm, material quality HARDOX 450/ front protection hood/ front tipping ram for for easy tipping and optimisation of the stability during tipping/ two-hose quick lowering system for fast tipping cycles/ body end at top designed as pointed roof, soil or stones does not remain on it/ hydraulic opening rear tailgate, additionally pendulum mounted at top to avoid damages through big stones, cutting edge all around for light and reliable closing of tailgate/ robust rubber supports between body and chassis/ bolted mudguards adjustable in width with a steep angle of attack and therefore self-cleaning

Other: 40 km/h homologation according to type approval EU (VO) 167/ 2013/ operating instructions/ robust lamp housing with pointed roof at vehicle rear, high-quality rear lights with shock-resistant lens, LED lighting system, white front position lamps, yellow side marker lamps, rear position lights/ exchangeable, modularly designed rear underride guard/ shot peened frame/ painting 2-component paint in Krampe-red (similar to RAL 3002) satin-finish

This trailer (Halfpipe HP 20 Carrier) is equipped with a fixed, high-quality standard specification.

This model is also available as a customised version:

Cookie-Consent

Cookie-Consent